Manufacturing Facility Overview

| Dosage Forms | Range |

| Tablets | Immediate, Extended, Delayed & Modified Release |

| Capsules | Hard Gelatin Capsules |

| Topicals | Ointments, Creams, Gel, Shampoo & Lotions |

| Nasal Spray | Metered dose |

| Oral Liquid | Syrup & suspension |

| AREA | LOCATION | FLOOR SPACE IN M2 |

|---|---|---|

| Ground Floor | TOPICAL (MFG/FILLING & PACKING) | 329 |

| RM/PM STORES | 467 | |

| ORAL LIQUID FILLING & PACKING | 137 | |

| TABLETS CAPSULES PRIMARY & SECONDARY PACKING | 147 | |

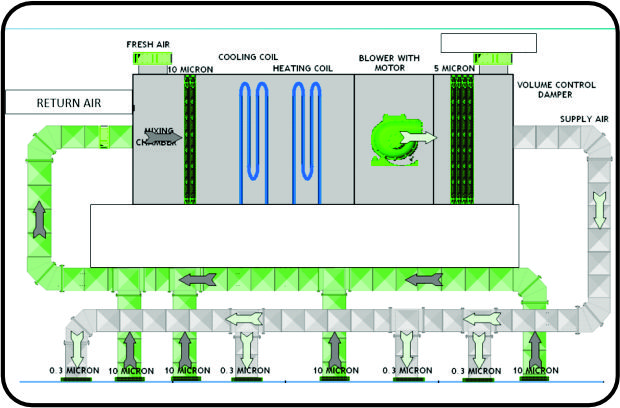

| First Floor | UTILITY & SERVICE OF AHU | 572 |

| Second Floor | TABLET MANUFACTURING | 409 |

| ORAL LIQUID MANUFACTURING | 180 | |

| CAPSULE MANUFACTURING | 165 | |

| Third Floor | QA & QC | 216 |

| SERVICE AREA | 1662 |

WAREHOUSE DISPENSING AREA / SAMPLING AREA

TABLET SECTION

CAPSULE SECTION

ORAL LIQUID SECTION

TOPICAL SECTION

Manufacturing :

Three Tank concept Mfg. line.

Having provision of preparation of Wax, Water phase separately and Mixing tank for mixing of both the phases.

Heating & cooling facility.

Water/Wax – Stirring Facility & Mixing Vessel – Stirring along with Homogenization facility.

Manufacturing vessel mounted on load cell.

Capacity :

Mfg Line 1 : 600 Kg

Mfg Line 2 : 2000 L

Packing :

Capability for filling of lami and Plastic Tubes/J ars.

Packing lines

Tube Filling

Capacity : 25000 Tubes /shift

Lotion/Jar/Bottle Filling

Capacity : 12000 Bottles/shift

MANUFACTURING AREA